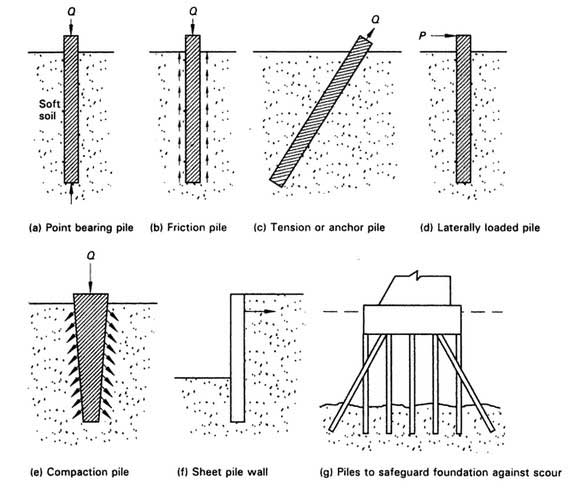

What Is The Style Strategy For The Spacing Of Min-piles? Most Significant Civil Design Info Sharing Web Site On the other hand, mini loading has likewise been used efficiently for major frameworks such as bridges as well as overseas wind ranches. The two primary ways of inserting heaps are driving, where the heap displaces the dirt rather than removing it first, as well as boring, where you produce an opening for concrete or cement to be poured into. There are many means to reinforce a building's structures-- however none are as reliable as well as flexible as stacking. At Structville, we stop at absolutely nothing in offering you new measurements to the career of civil design. The bearing aspect that sends out the load to the layer of soil or rock that is lugging the lots. A helical heap is a type of support in which helical bearing plates are affixed to a round cross-section shaft. They are offered in sizes of 19 to 63 mm with yielding strength approximately 550 MPa. The thread on bench makes sure a strong bond with the concrete grout. Micro stacks as discussed earlier are screwed right into the soil to enhance its bearing capability. The installation of heaps should be done in such a manner in which the load-carrying capability of the earlier installed heaps is not decreased. The sequence of installation of stacks in a stack group is mainly from the center to the periphery of the group. A rich grout of cement and fine sand with a water-cement proportion of 0.5 is used to grout the stack. The grout should have a compressive stamina of a minimum of 480 kg/cm2 on 28 days. Micropiles can additionally be labelled as bored piles if their size is less than 250 mm. Bored piles are usually made from concrete and birthed down the planet to move lots from the foundation to the tough strata below. Micropile structures are conveniently mounted and also are extremely light-weight so are quickly managed. This will identify just how deep the piles need to be placed in order to support the tons positioned on them. Piles put in locations with high groundwater degrees will certainly need to be able to withstand hydrostatic stress. The third factor is the sort of rock or soil the heaps will certainly be driven right into. This will impact both the installation process and the long-lasting efficiency of the structure. Ultimately, it is important to consider the climate and climate condition in the location where the foundations will certainly be installed.

35 Products That Are — Gasp — Useful *And* Pretty - BuzzFeed

35 Products That Are — Gasp — Useful *And* Pretty.

Posted: Tue, 15 Aug 2023 21:01:03 GMT [source]

Overviews To Mini Piles

According to (), abilities of about 500 tonnes have additionally been attained. When micropiles are pressure-grouted in place for higher capability, the family member thickness as well as side stress of the bordering dirt is raised, consequently leading to substantially higher shaft resistance. In short, this article explains the style and setup procedure of micropiles. Modified after Rotta Loria, A.F., Català Oltra, J.V., Laloui, L., 2019b. Equal pier evaluation of major heap teams subjected to mechanical and thermal loads.LG G3 OLED TV Review: The New Picture Quality Champ - CNET

LG G3 OLED TV Review: The New Picture Quality Champ.

Posted: Sun, 13 Aug 2023 11:00:00 GMT [source]

Micropile And Minipiles

On top of that, micropiles can be mounted with preexisting structures and also for the base of frameworks and also repair service of malfunctioning structures. The best internal resistance of an upright heap as well as the deflection of the heap are complicated issues entailing the communication in between a structural element as well as the soil. Taking the situation of an upright stack unrestrained ahead, the lateral loading on the stack head is at first lugged by the dirt short surface. At a reduced loading, the dirt compresses elastically, yet the motion suffices to move some stress from the pile to the dirt at a better deepness.- As the drilling procedure progresses, the dirt is gotten rid of from the borehole by the excavation technique.Driven piles, on the various other hand, are forced right into the ground, to make sure that the surrounding dirt supports them.Basically, this article explains the layout as well as installation procedure of micropiles.The predictive accuracy, model interpretability, as well as parametric level of sensitivity evaluation of the established BPNN pile settlement design are demonstrated.